A Flying Extruder for the Bondtech's BMG or LGX extruder (or a clone like the DDG from Triangle-Lab) which main advantages is to produce almost no ghosting, is cheap to build and can be setup very quicly. This module is compatible with most of the delta 3D printers including the Anycubic Kossel models and virtually any Kossel.

Features and advantages

For this implementation of a Flying Extruder, I did not use, as is usual, a suspension system based on bungee cords or rubber tubes. In my configuration, the extruder is supported by badge holders with retractable wires attached, not to the carriages, but to the structure of the printer.

This simple trick allow to reduce the weight on the head and print faster while reducing ghosting effect.

Flying extruder Fusiology v4 with DDG Extruder version 1.0 from Triangle-Lab.

Flying extruder Fusiology v4 with DDG Extruder version 1.0 from Triangle-Lab.

With this system the weight applied to the head is greatly reduced compared to systems where the extruder is attached to the X, Y, Z tower's carriages. The advantageous consequences are that you can print faster and with better quality. The ghosting effects, in particular, is very reduced.

The head stays in place even when the engines are turned off. The head will not fall due to the added weight of the extruder and motor couple.

The other advantages are those found with a classic Flying Extruder, namely:

- Better extrusion/retraction than with a classic Bowden system (for example: the stringing effect is greatly reduced).

- Ability to print soft materials like TPU.

Cost and ease of manufacturing

Theere are only good news here : this upgrade is suêr easy to build and costs almost nothing. A box of 4 badge holders, like the ones I use, costs less than 10 euros. I decided to use 6 badge holders to hold my extruder because the BMG/DDG extruder with a Pancake type NEMA 17 stepper motor remains a fairly heavy assembly. With a lighter extruder/motor pair, you could probably only use 2 or 3 badge holders to get the job done. For example with a Sherpa Mini extruder with its NEMA 14 motor, 2 badge holders are enough to hold the extruder in place.

My model for the Flying Extruder type system only has 2 parts to print. The parts require no supports or post-processing and are assembled with a minimum of screws and a few cable ties.

Note that I use this mod on an Anycubic Kossel Plus printer but it can be suitable for all delta type printers in general. The trick of using retractable badge holders as attachments can be used for other configurations and types of 3D printers and can be set up in 10 minutes flat to complement or replace an existing attachment system.

Making the Flying Extruder Fusiology v4

Links to merchant sites to find the mod components are at the end of the article.

You need a BMG extruder from Bondtech or a compatible clone to make this mod. I use a much cheaper clone of this extruder: the DDG Extruder version 1.0 from Triangle-Lab and I am very happy with it. This has been my main extruder for years and has never failed me. Be careful when purchasing, for a Kossel or delta printer you will probably have to take the mirrored (left) version: it is the one with the wheel and the lever located on the left side when looking at the front of the extruder .

This is what a left BMG extruder looks like:

The building steps

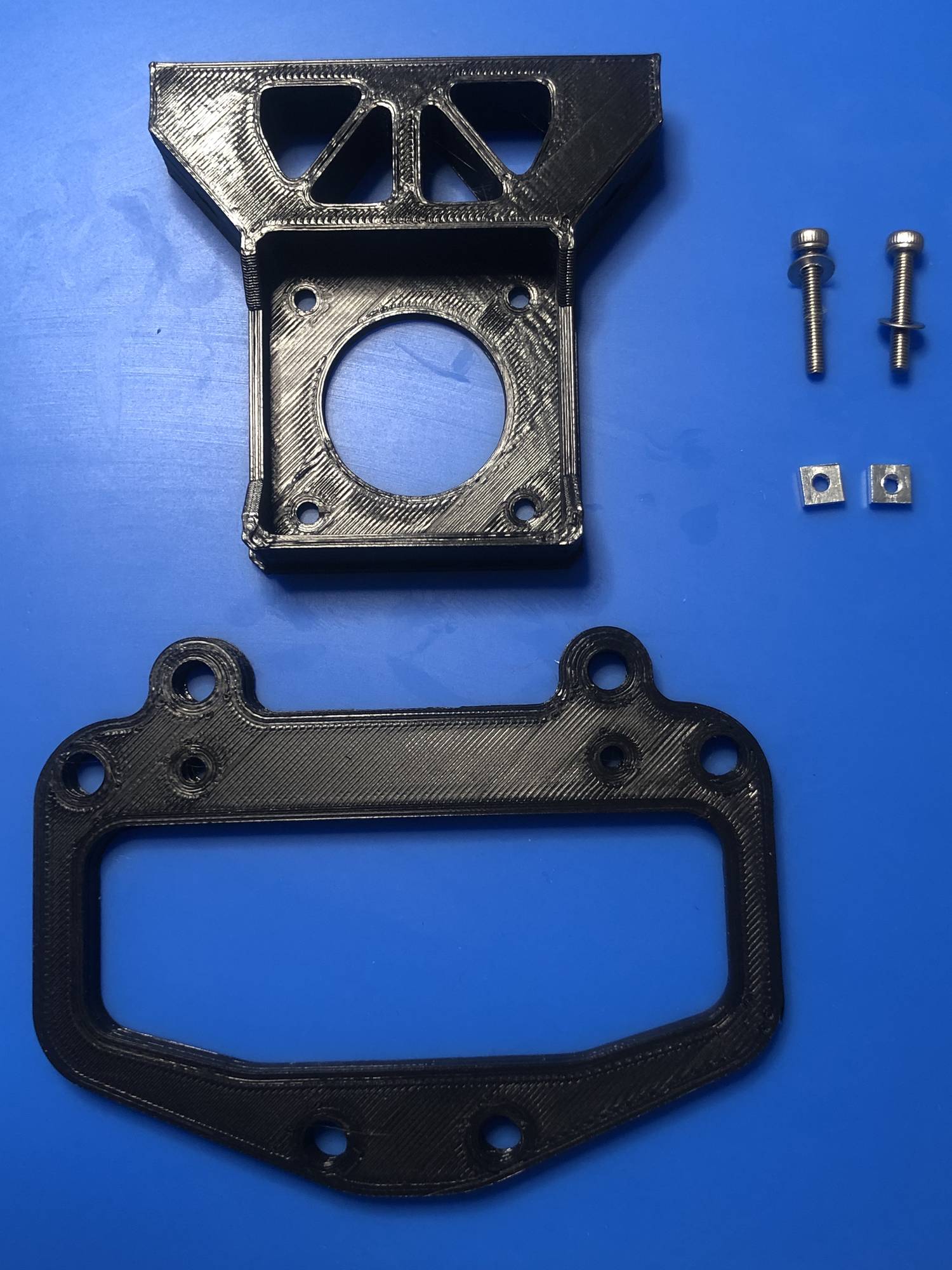

Download (download links at the end of the article) and print the 2 pieces that compose the extruder's support. The recommended material to print the parts is ASA.

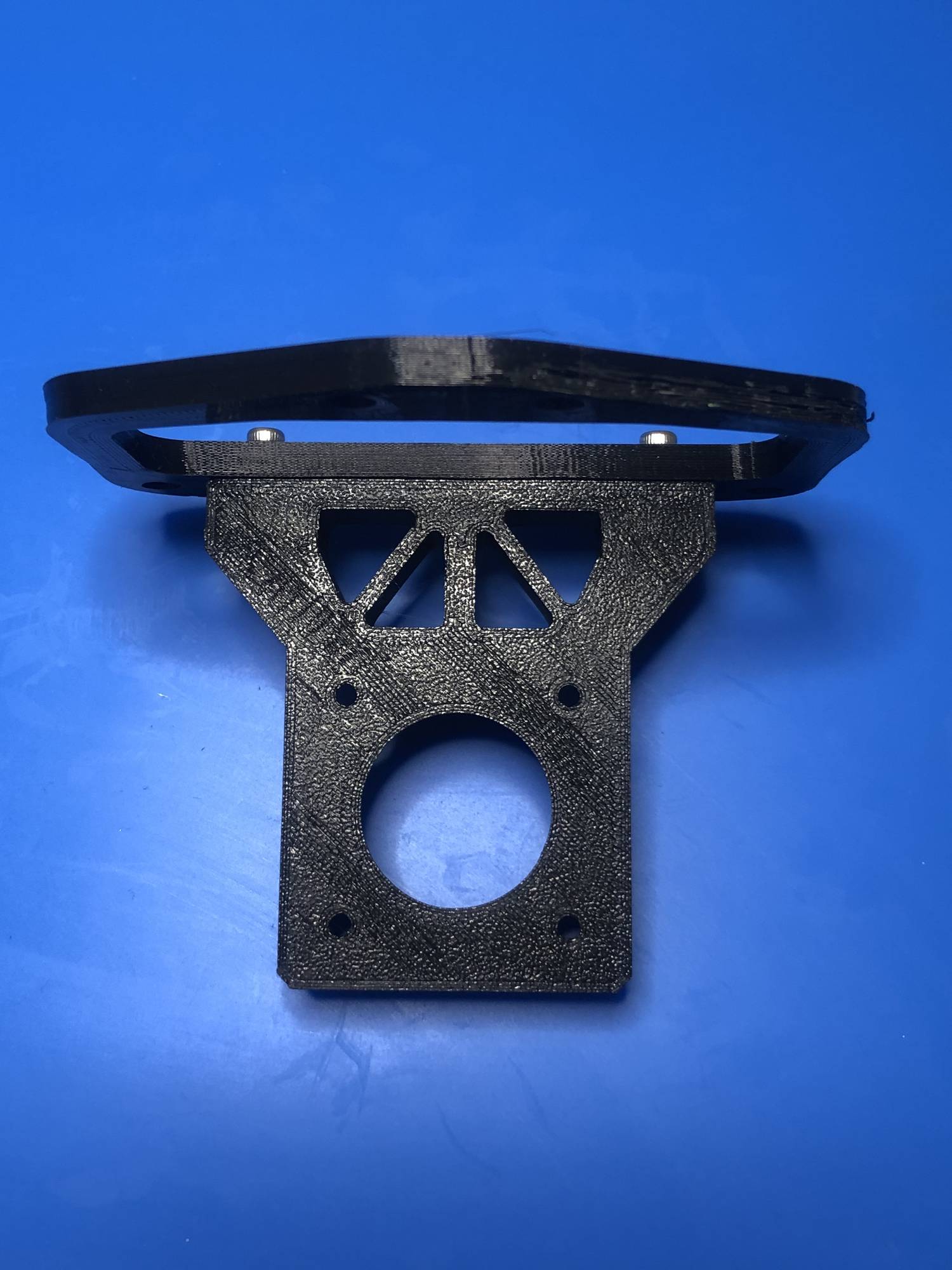

Assemble the parts with two M3 screws, two washers and two square nuts:

With a cutting pliers, remove the plastic part that holds the snap button:

Attach each ring to a free hole on the extruder's support :

Fix the BMG/LGX/DDG extruder and its stepper motor using the 3 included HEX screws:

Attach the badge holders to the printer frame as shown in the photos. I used Velcro cable ties, as I find them convenient for maintenance, but you can use ties of your choice:

And the assembly is completed! :-)

Before using it, remember to configure the extruder in the firmware.

Download

/models/fusiology-ligtweight-flying-extruder-version-4-anycubic-kossel

Required materials

- A Bondtech BMG/LGX type extruder, or a compatible clone, with its motor. I use the DDG v1.0 extruder from Triangle-Lab.

- The badge holders I use: https://amzn.to/3V9CJ1V

- Velcro cable ties: https://amzn.to/3v9yyZf

- 2 M3 screws with square nuts and washers. You probably already have this in stock already.