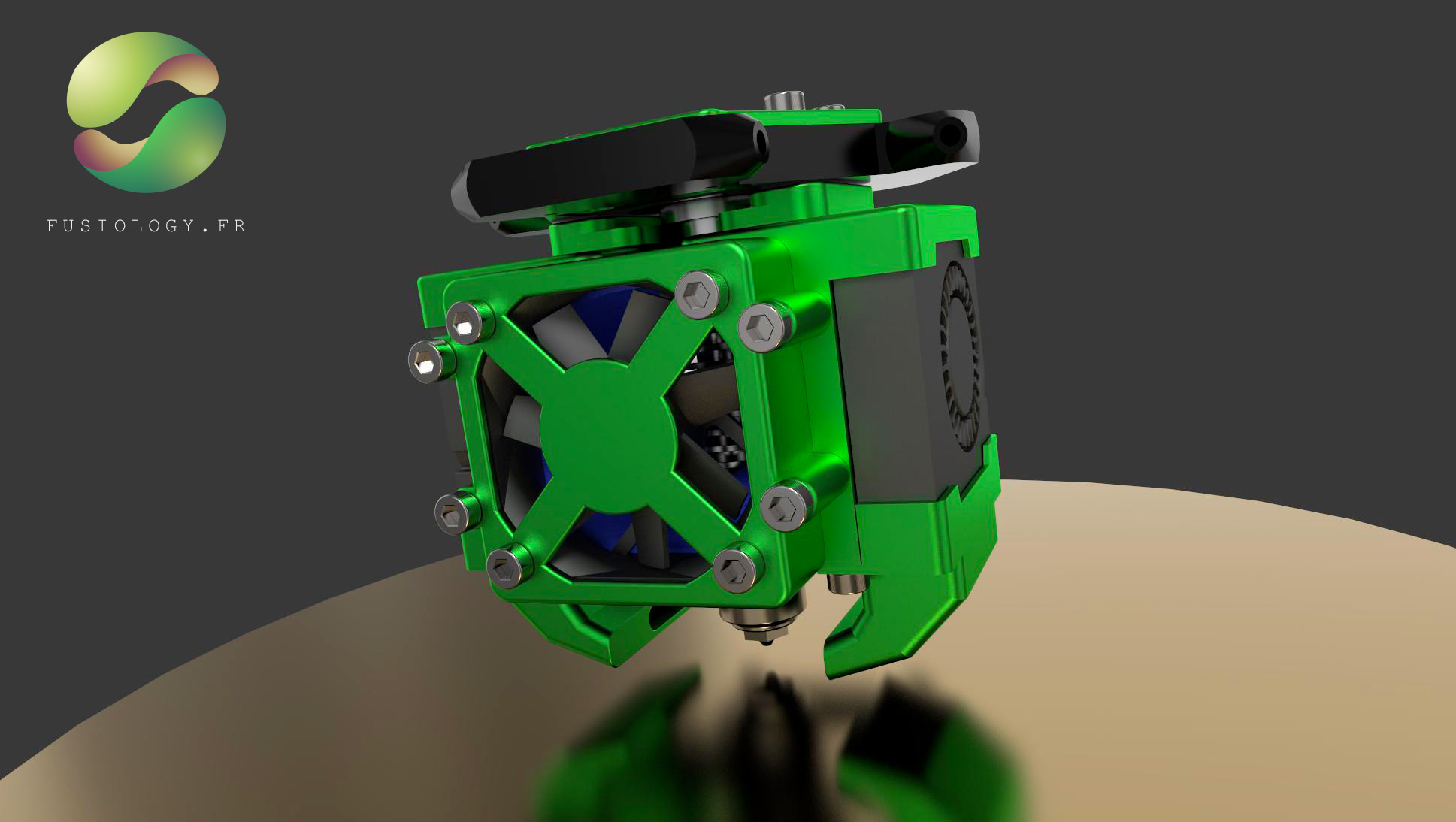

This toolhead is designed for the Anycubic Kossel Plus (Linear or Pulley) 3D printer but it can easyly be adapted for other models of Kossel. It brings support for E3D's hotends V6 and VOLCANO. It also fix the problem with Anycubic Kossel hotend clogging all the time.

Cette documentation est disponible en français : Fusiology Toolhead version 3.4 pour Anycubic Kossel Plus

Current version:

3.4.28

Main features :

- Support E3D's V6 and VOLCANO hotends and many clones.

- Works with the stock Anycubic Kossel Plus's effector.

- Support the stock Anycubic Z probe V2.

- Fix Anycubic Kossel hotend clogging all the time..

- Easy to build: print in PLA without supports, no manual post processing needed.

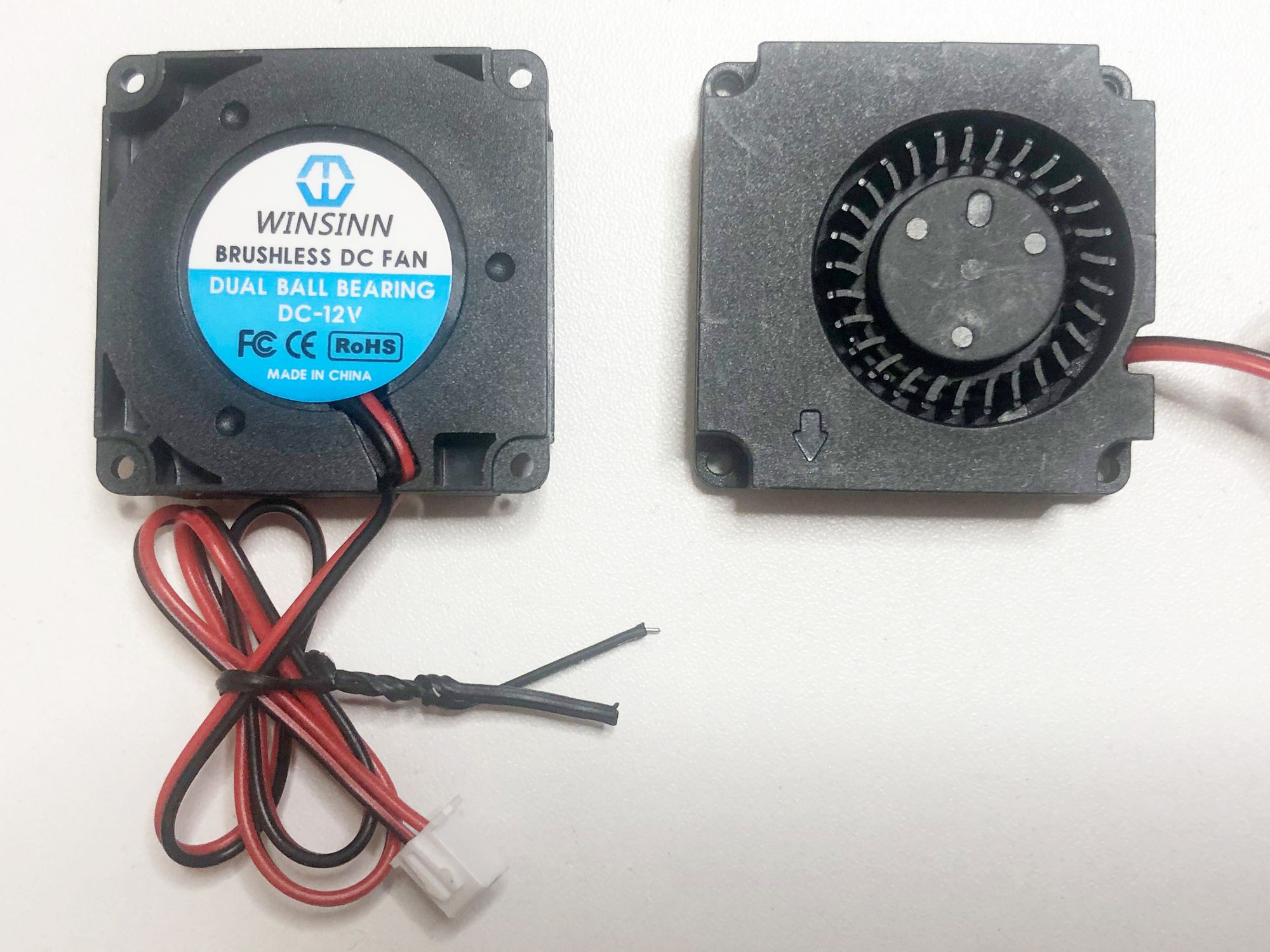

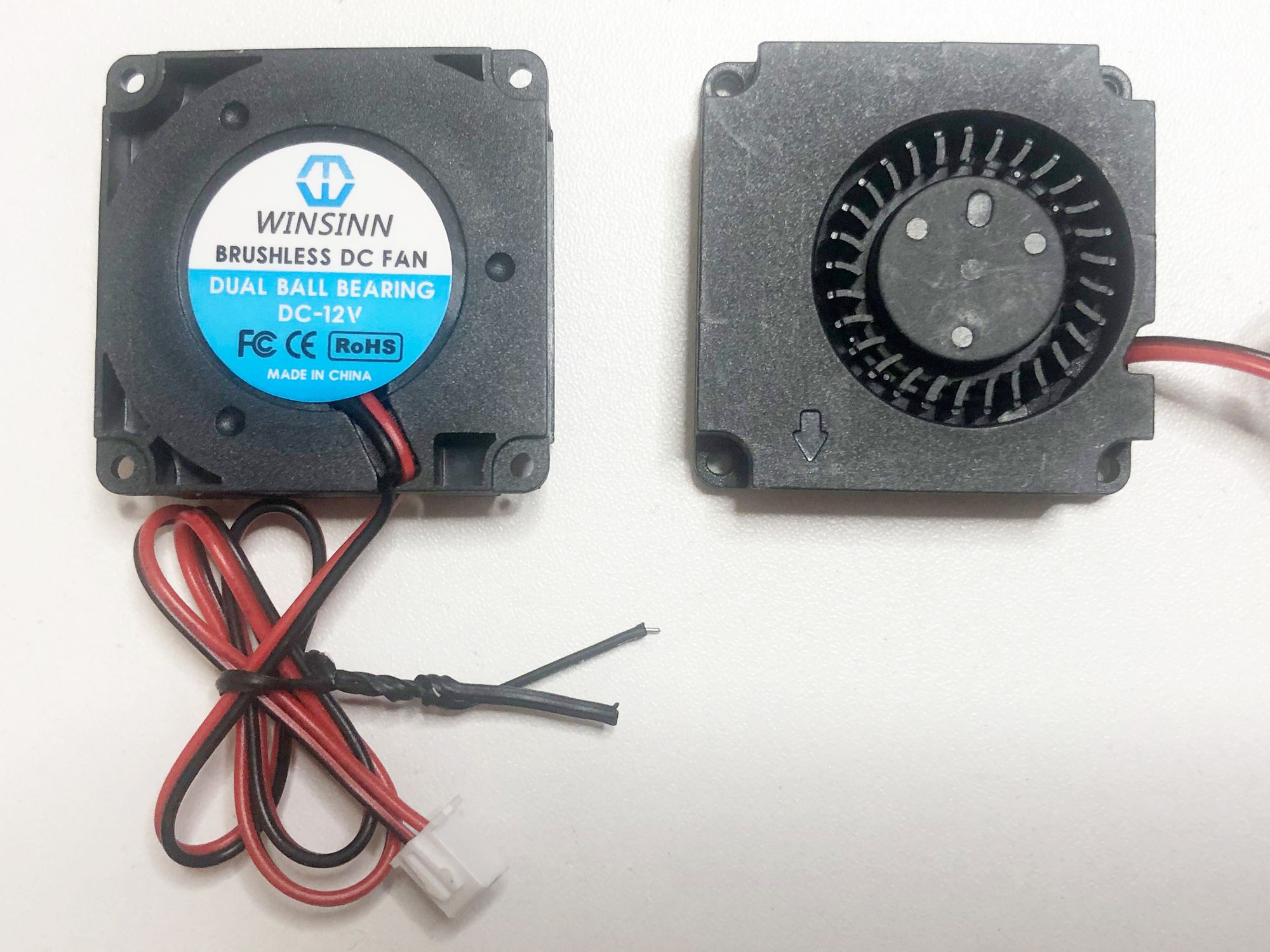

- Improved and silent part cooling system using 2 WINSINN 4010 silent blower fans.

- Support E3D V6 stock cooling system which is based on a 3610 fan. It is lightweight and efficient but very noisy.

- Optional improved and silent hotend cooling system based on a Sunon 4010 silent fan.

- Modular, easy to adapt, modify, hack...

Making

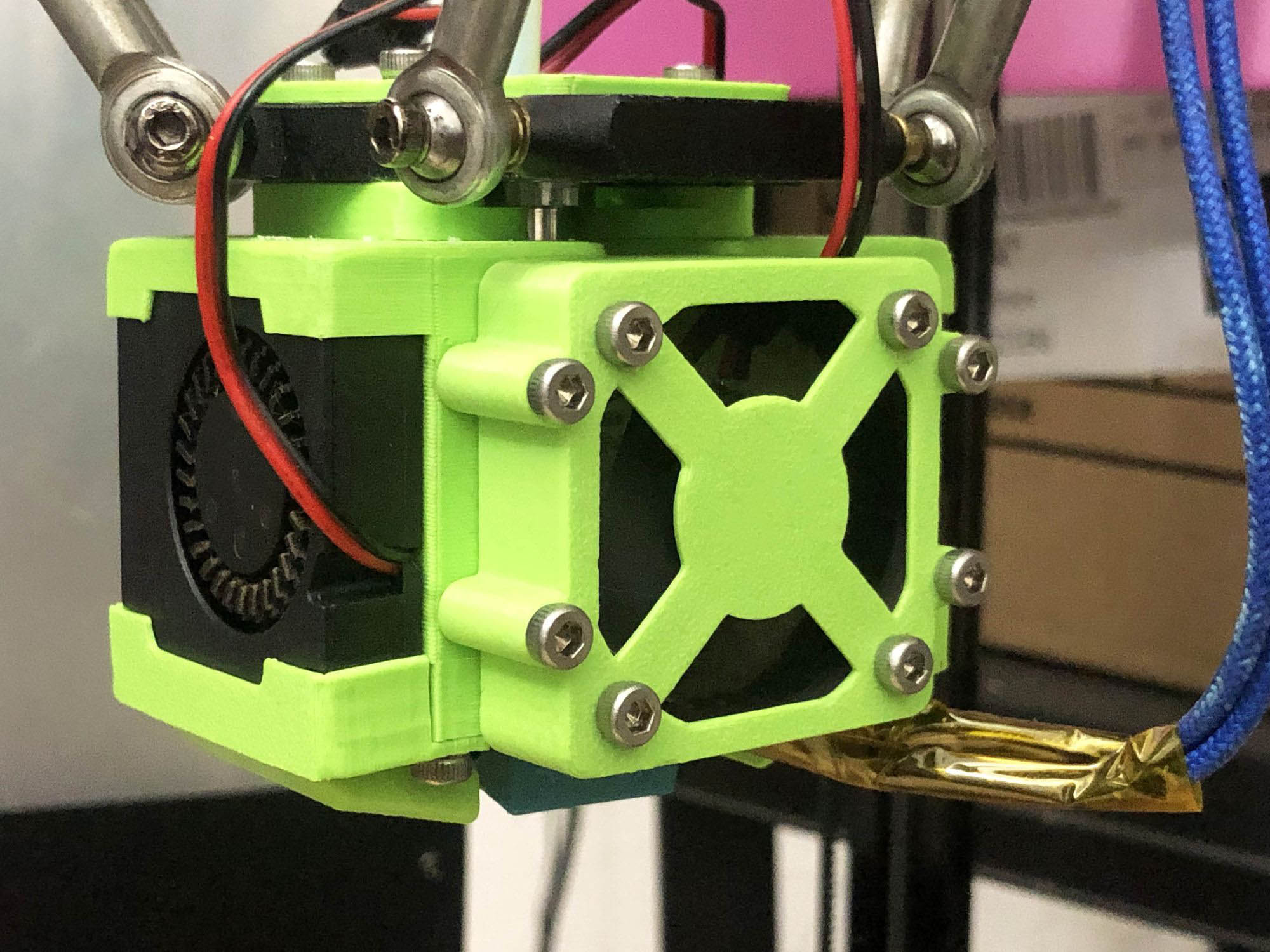

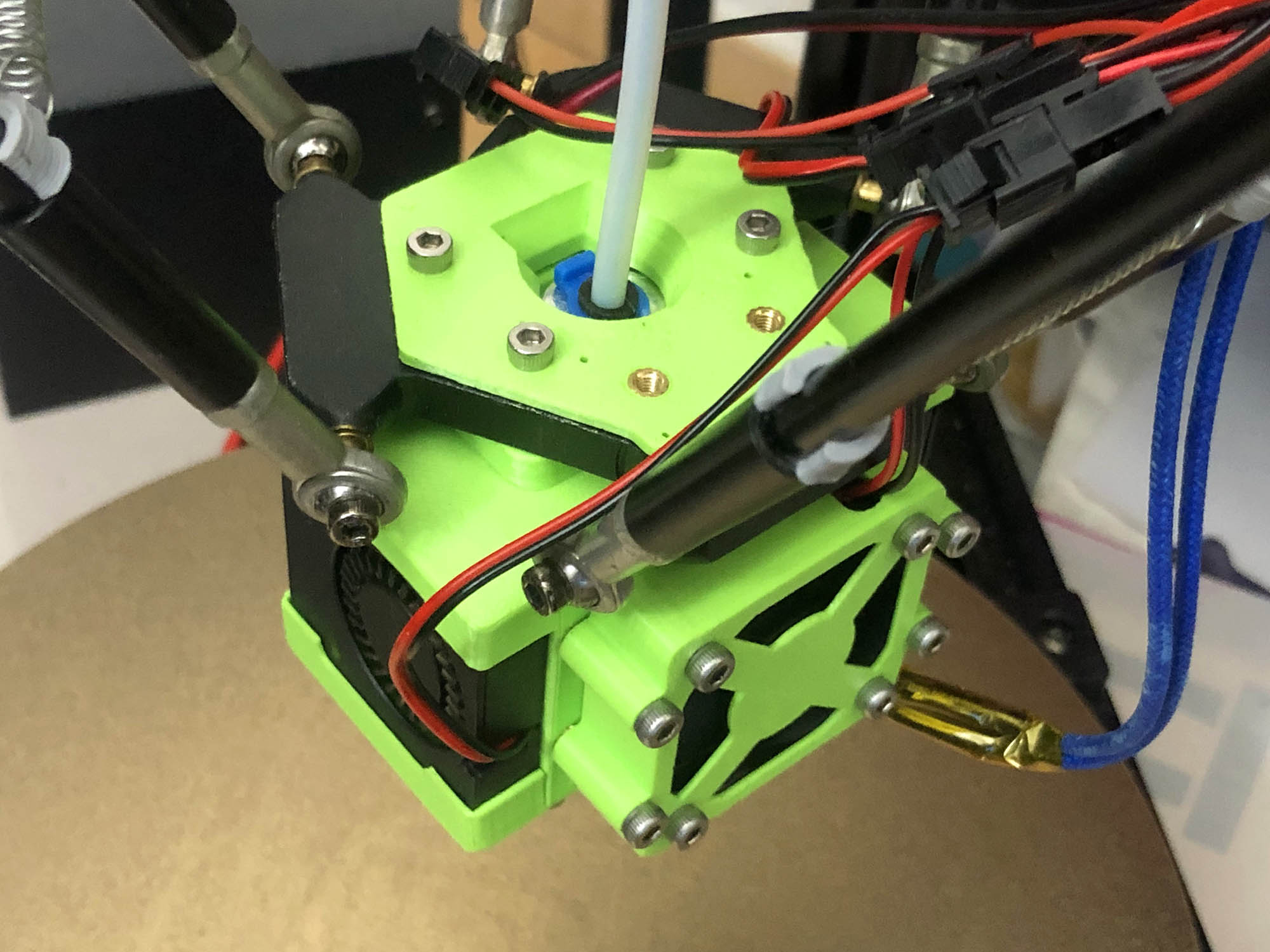

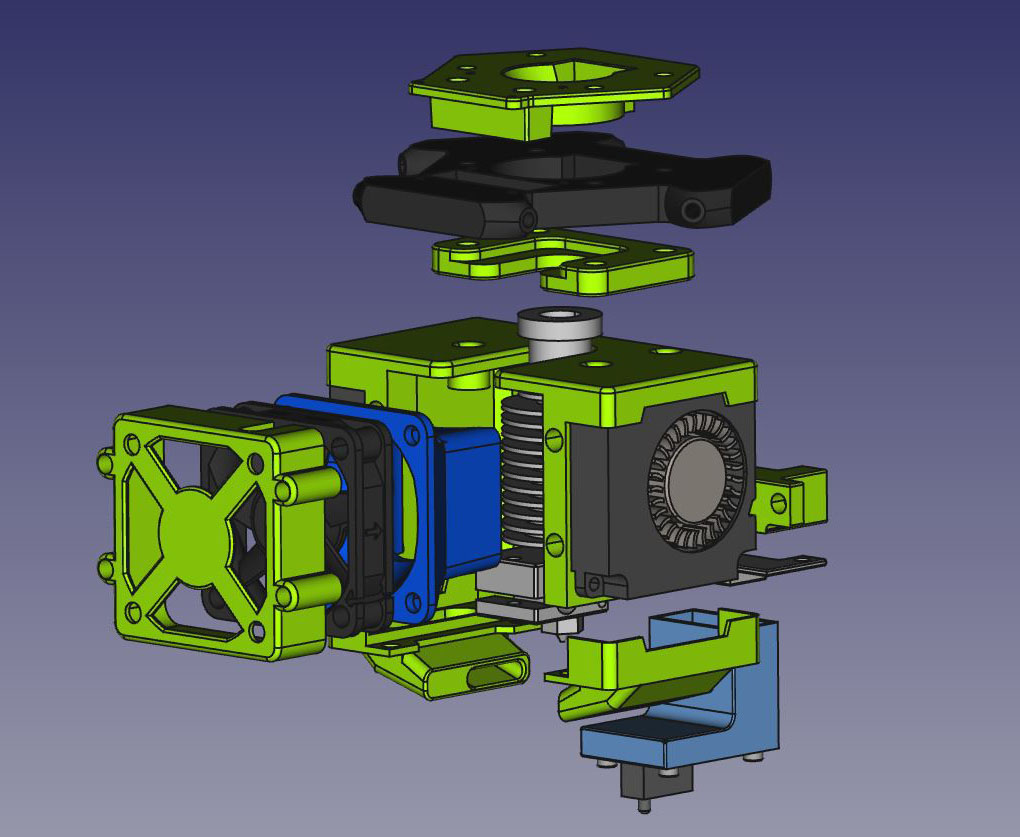

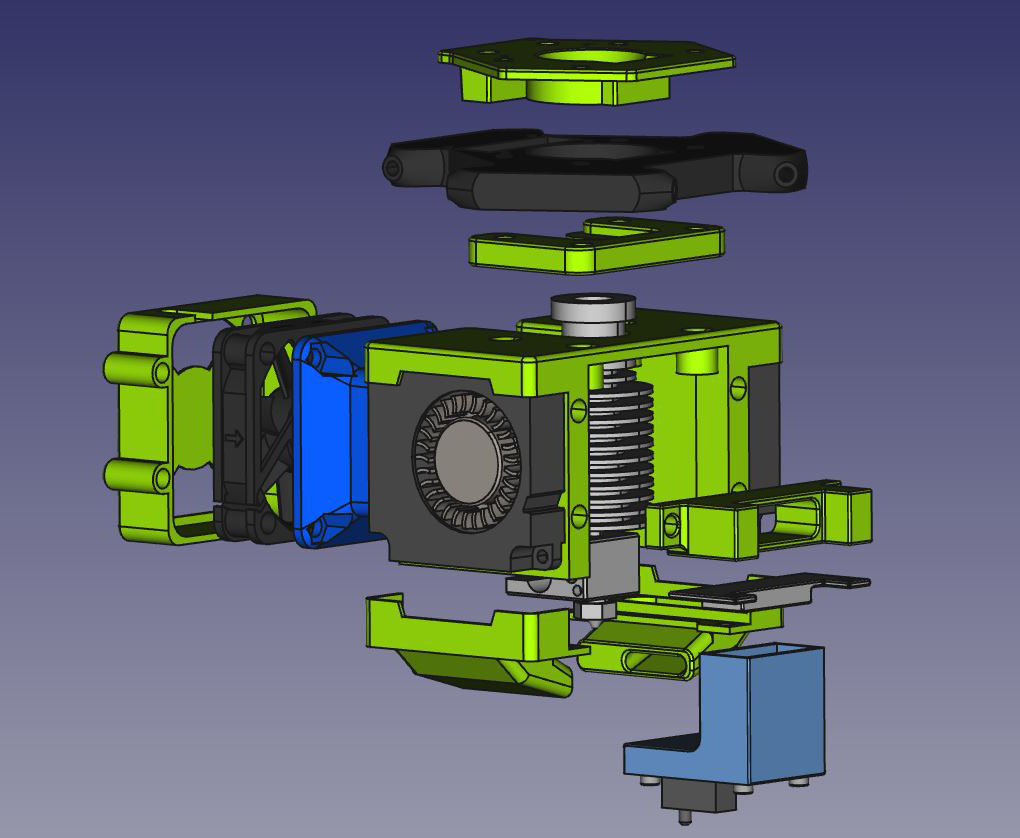

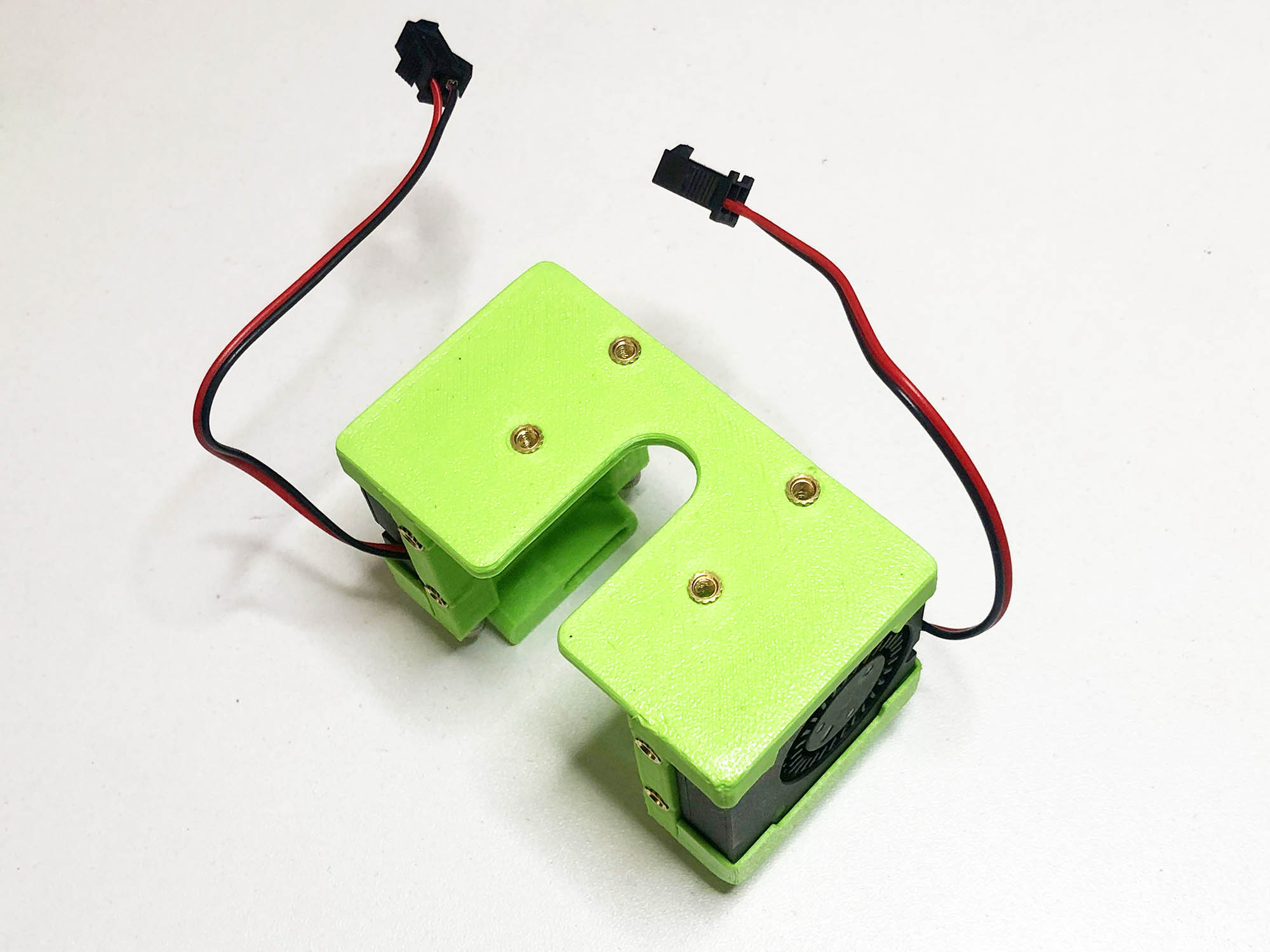

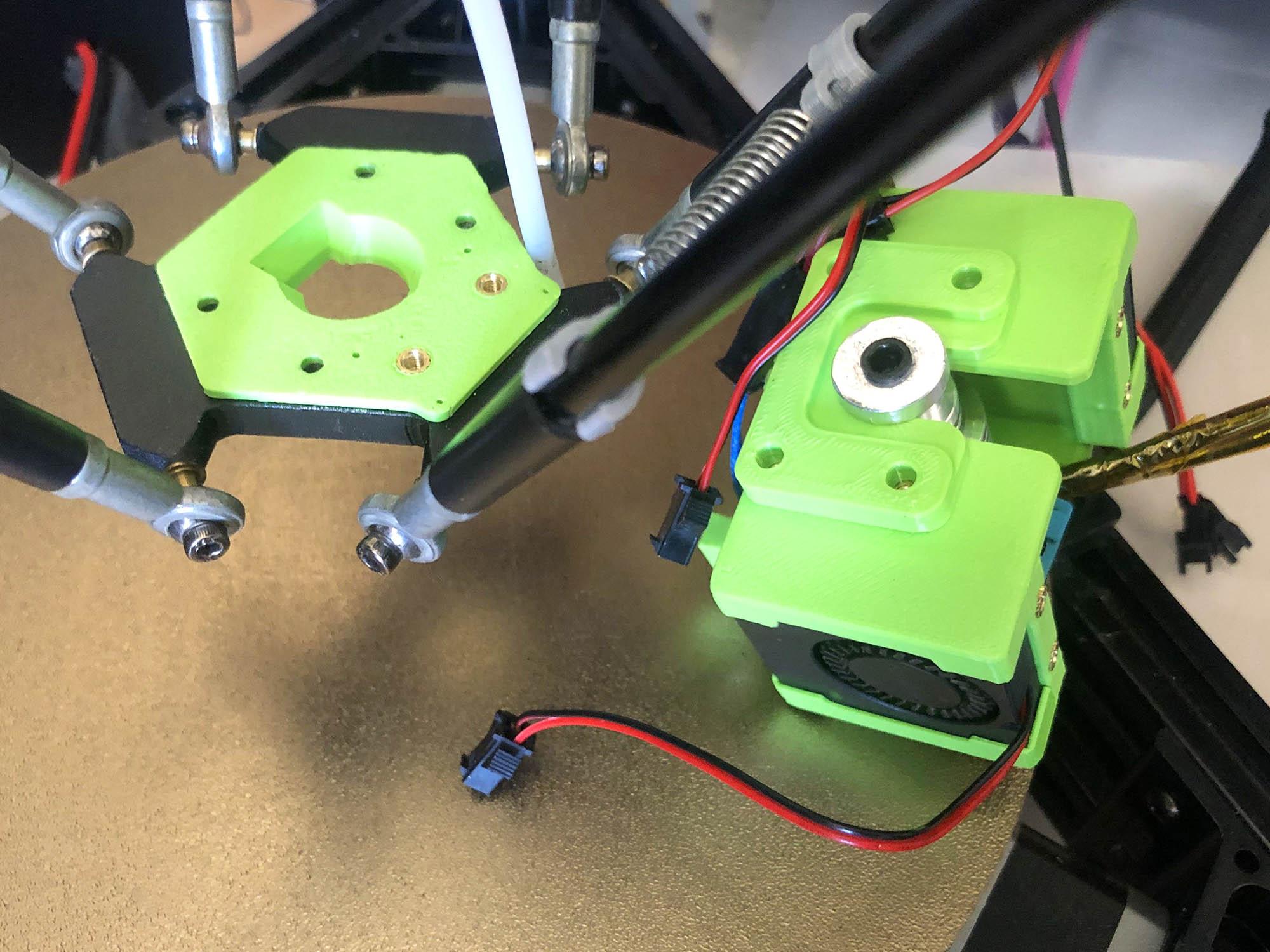

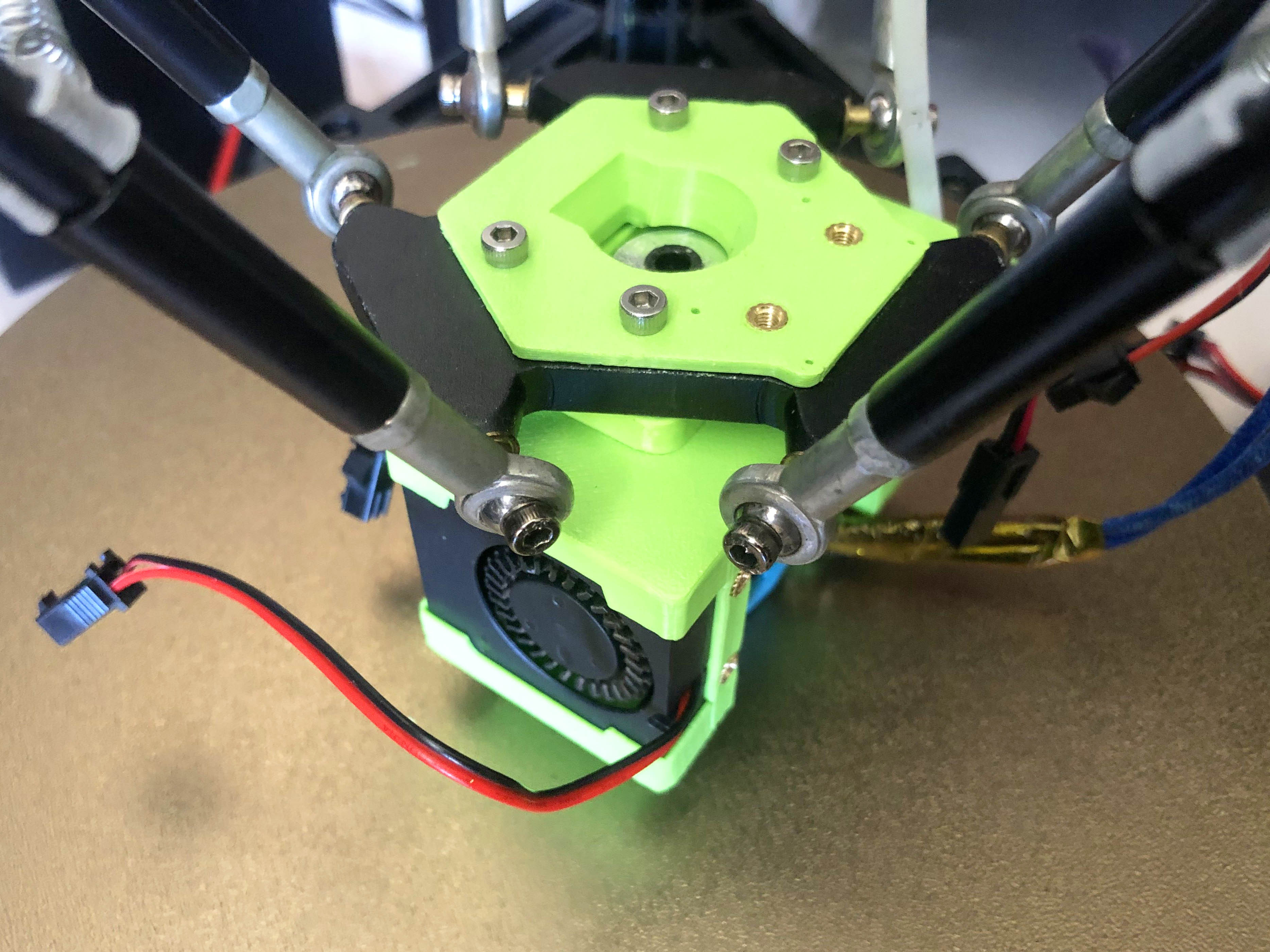

Here is an example of the toolhead assembled with an E3D-V6 hotend cooled by a 4010 fan:

Download the printed parts:

Fusiology Toolhead version 3.4 for Anycubic Kossel Plus

How to print it?

- All parts have proper orientation and are ready to print.

- Print without supports, layer height: 0.2 mm, infill density: 25%, infill pattern: triangles.

- No manual post processing needed.

- All parts can be printed in PLA/PLA+.

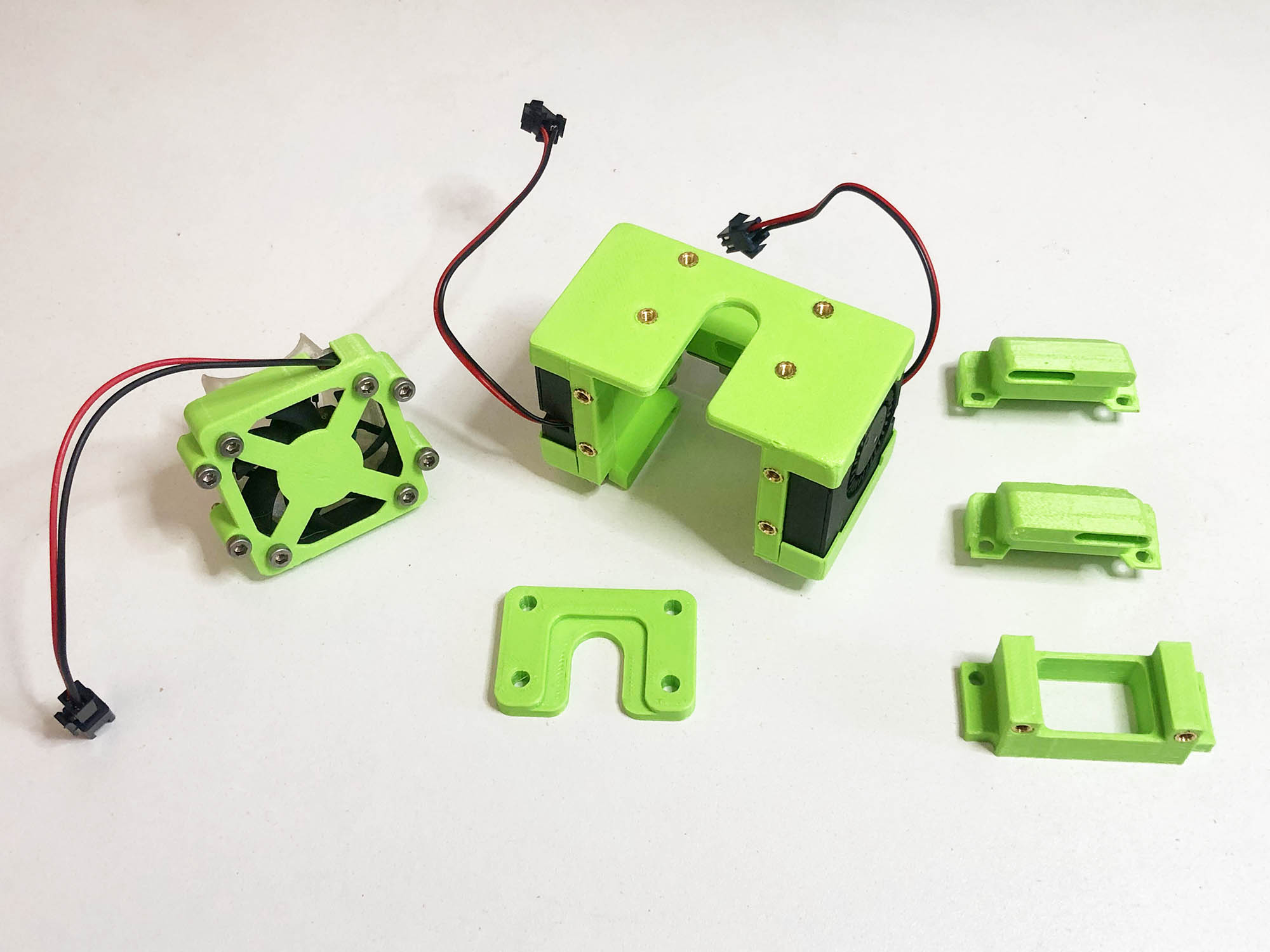

To build the toolhead print the following parts:

- body

- body_fixation_V6 (use the same file for VOLCANO type hotends)

- effector_top_plate

- part_cooler_fan_duct_V6_left or part_cooler_fan_duct_VOLCANO_left

- part_cooler_fan_duct_V6_right or part_cooler_fan_duct_VOLCANO_right

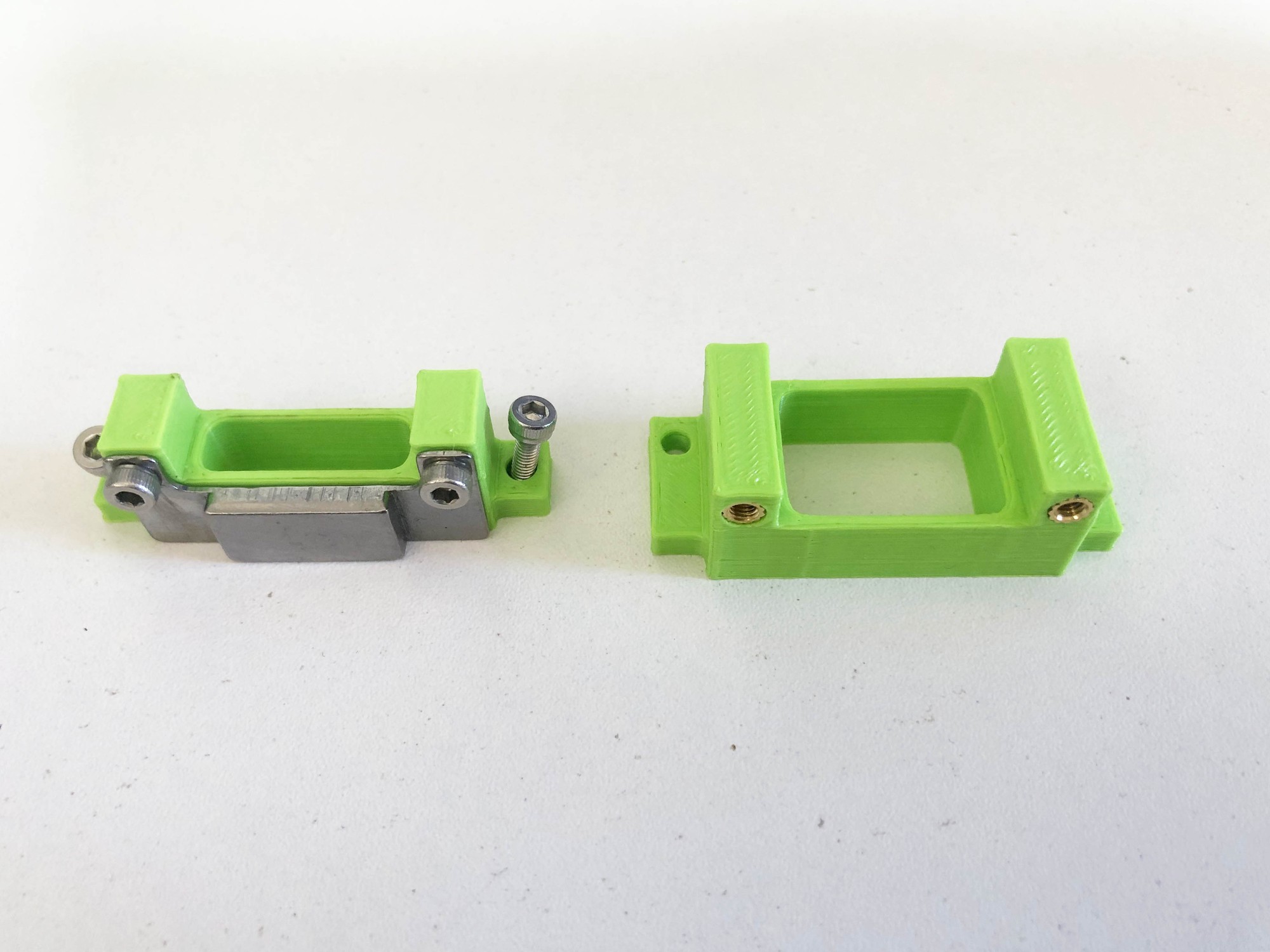

- Anycubic_Z_Probe_V2_mount_holder_V6 or Anycubic_Z_Probe_V2_mount_holder_VOLCANO

Some parts or available as V6 and VOLCANO versions. Pick the ones that matches the type of hotend you have.

If you choose to use the E3D V6 hotend stock cooling system, you don't need to print anything else.

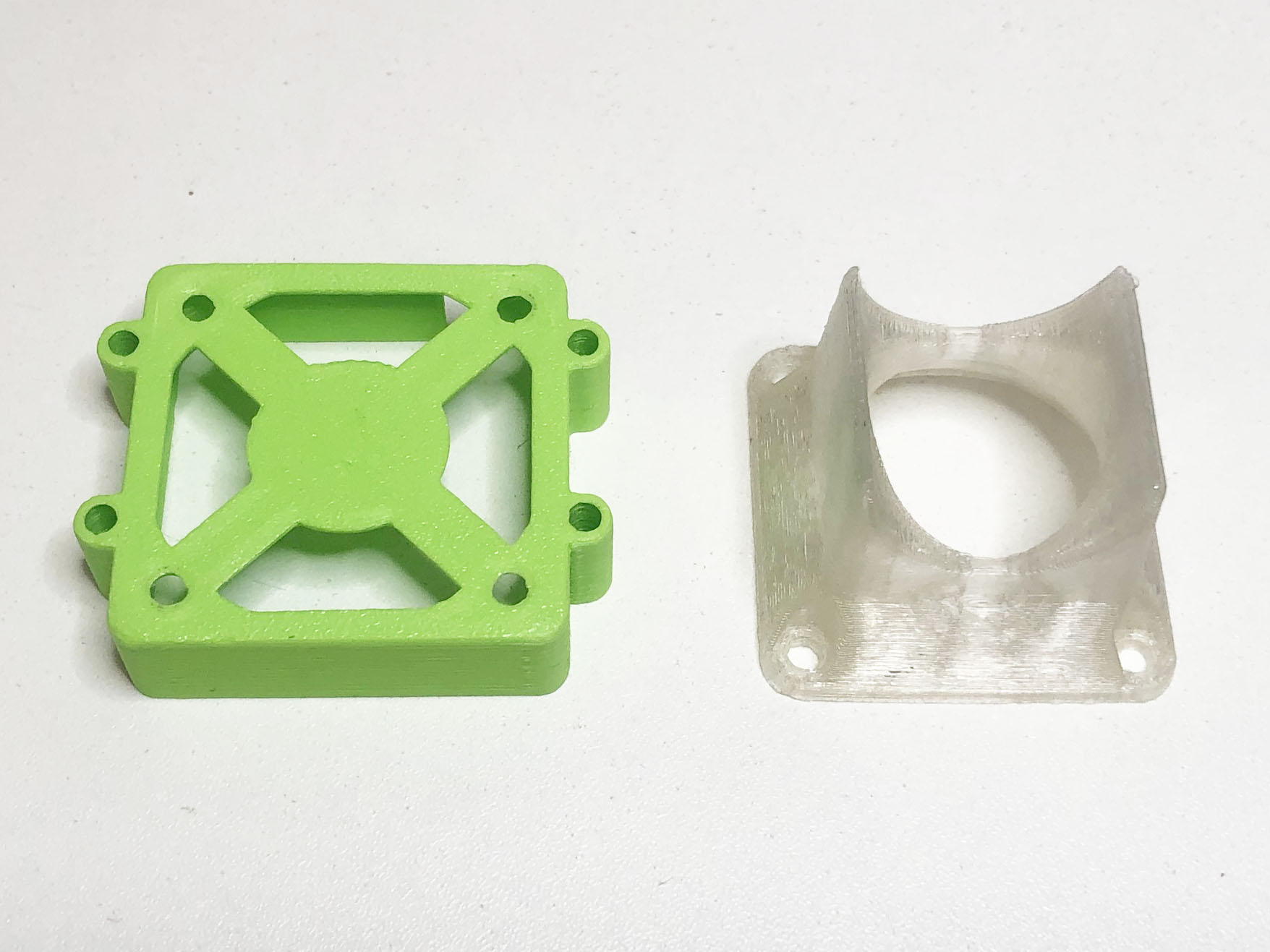

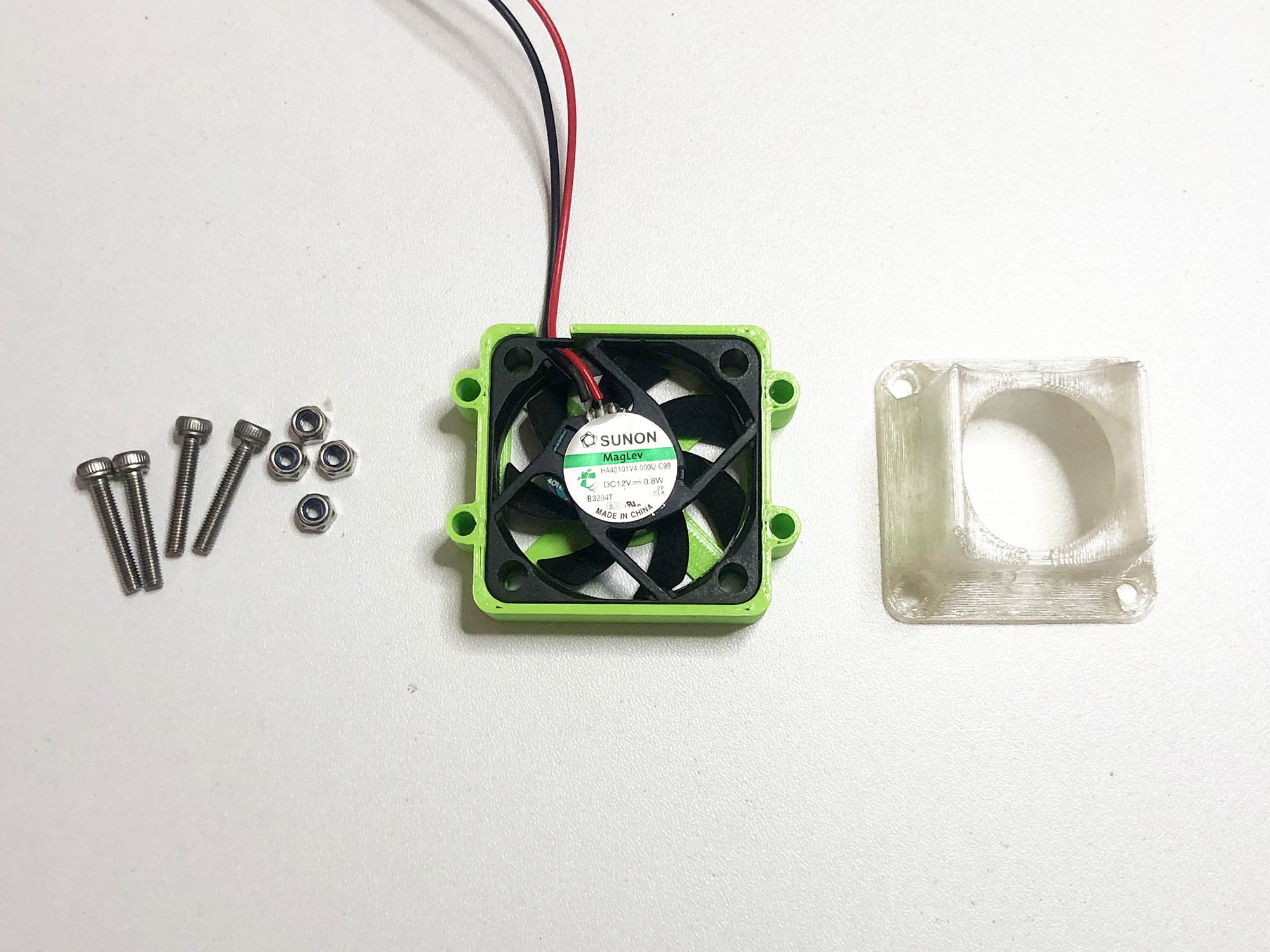

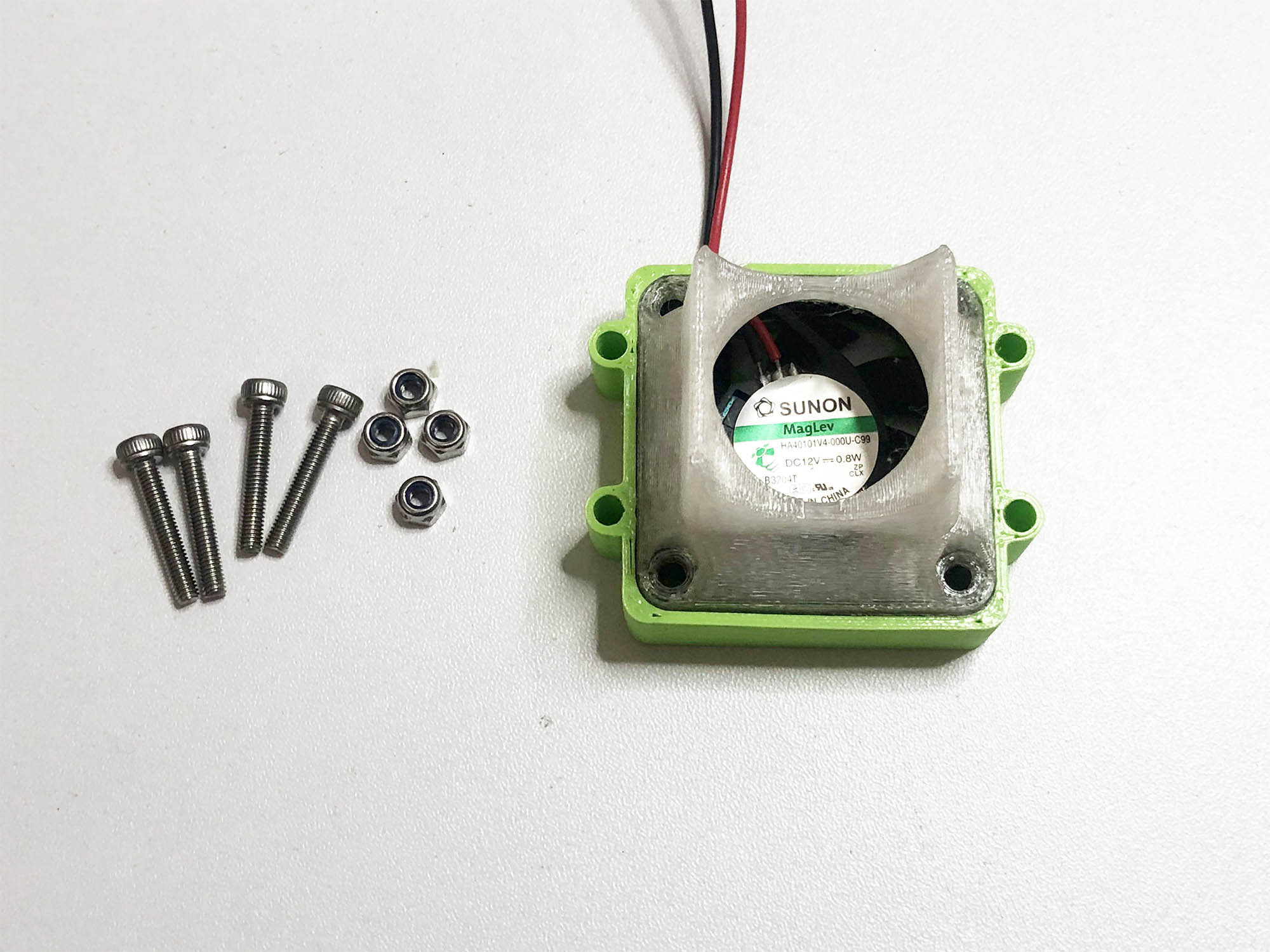

If you want to use the improved, silent cooling system for the hotend, you also need to print the following parts:

- heatsink_4010_fan_cover

-

heatsink_4010_fan_duct

Cooling fans

For the cooling of the printed part, I use 2 silent blower fans from WINSINN model FAN4010G12D.

You'll need to build a Y cable to connect both fans:

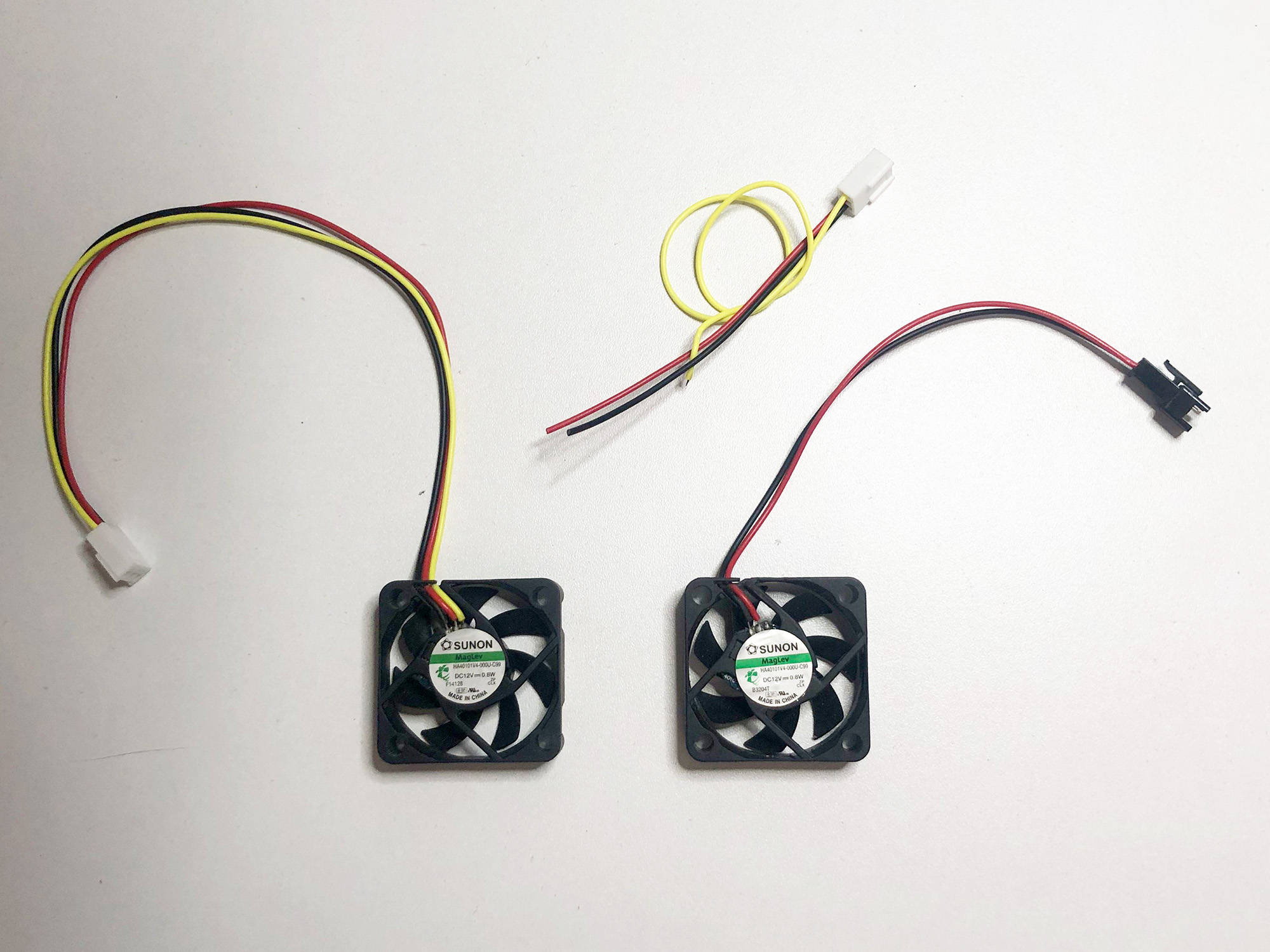

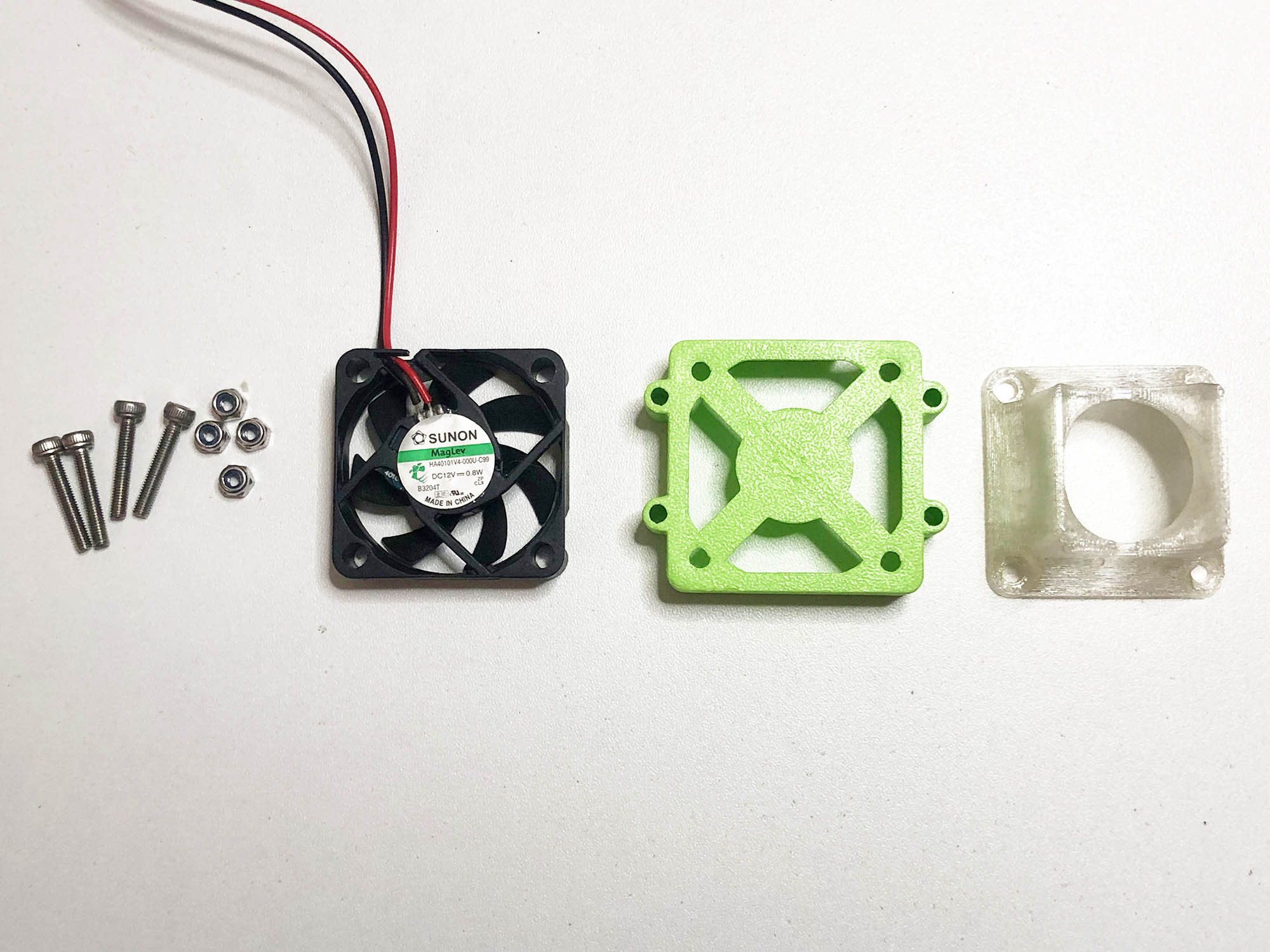

For the optional 4010 cooling of the hotend, I use a silent fan from Sunon familly MagLev model HA40101V4-0000-C99 12V 0.8W 0.06A 3pins. To connect the fan keep only the red and black cables and remove the yellow one.

I use SM type connectors to connect the fans but you can use whatever type you prefer or even solder the cables directly.J'utilise des connecteurs de type SM pour attacher les ventilateurs mais vous pouvez utiliser ceux de votre choix ou même souder directement les câbles.

Toolhead assembly

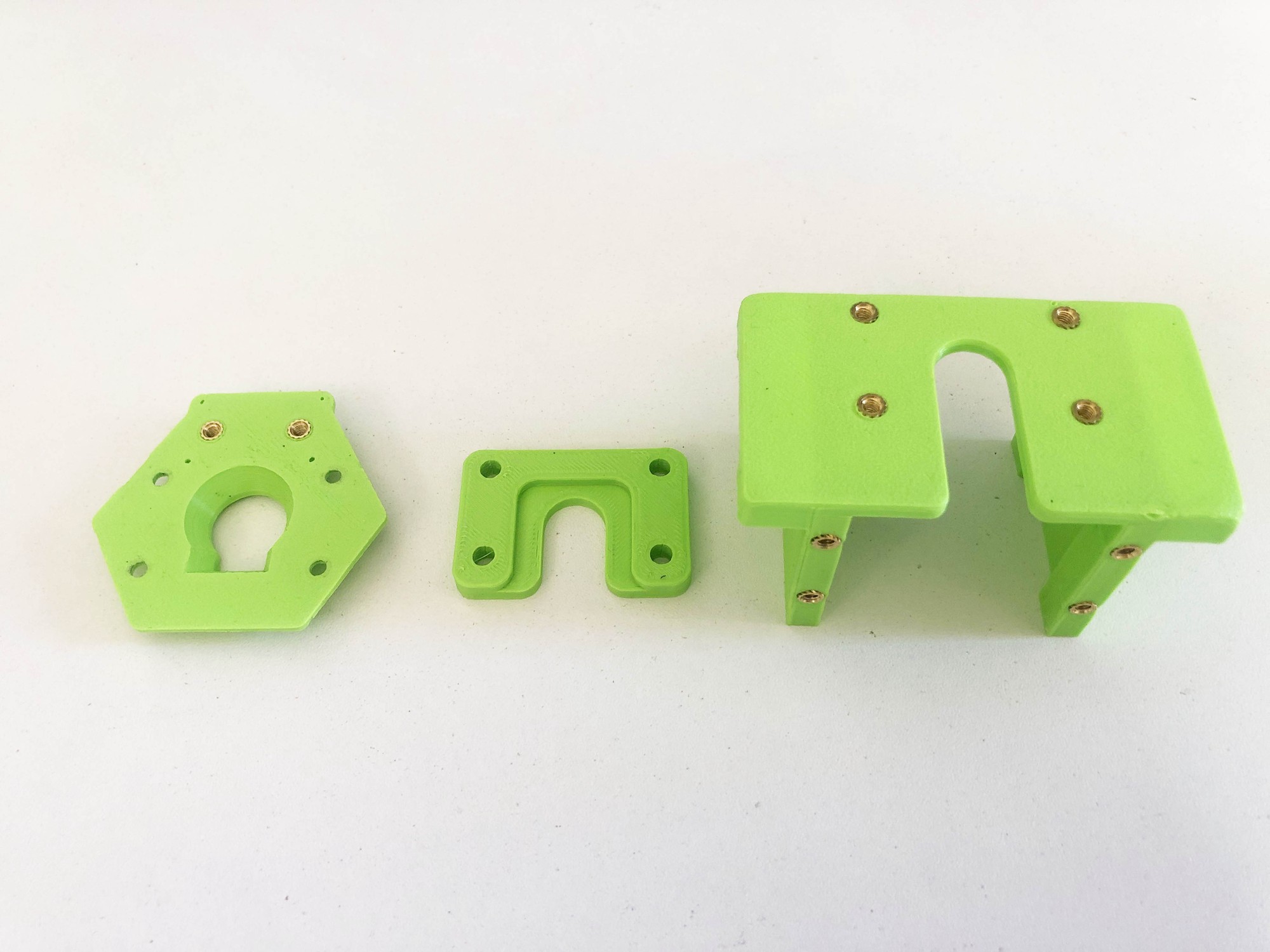

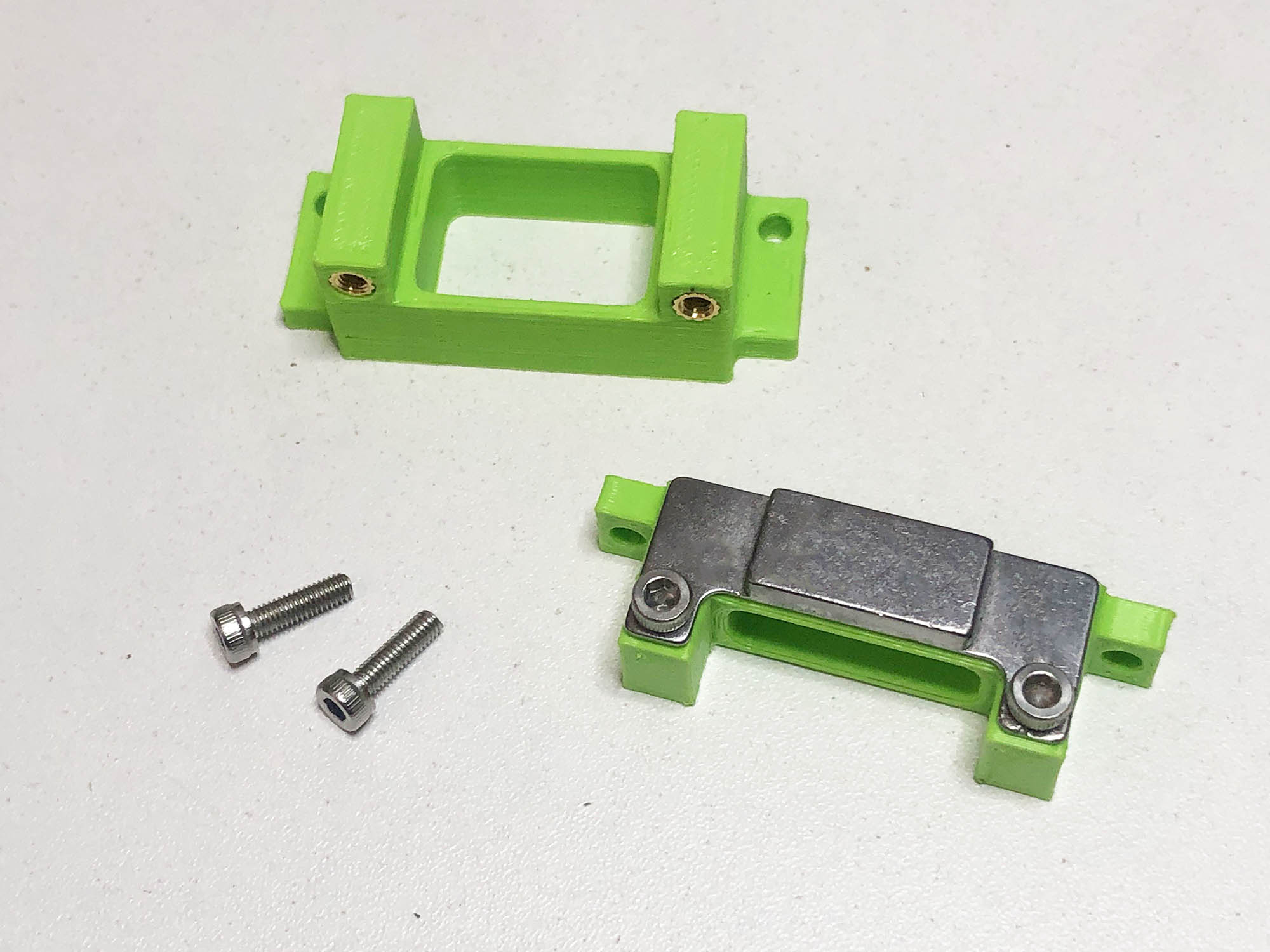

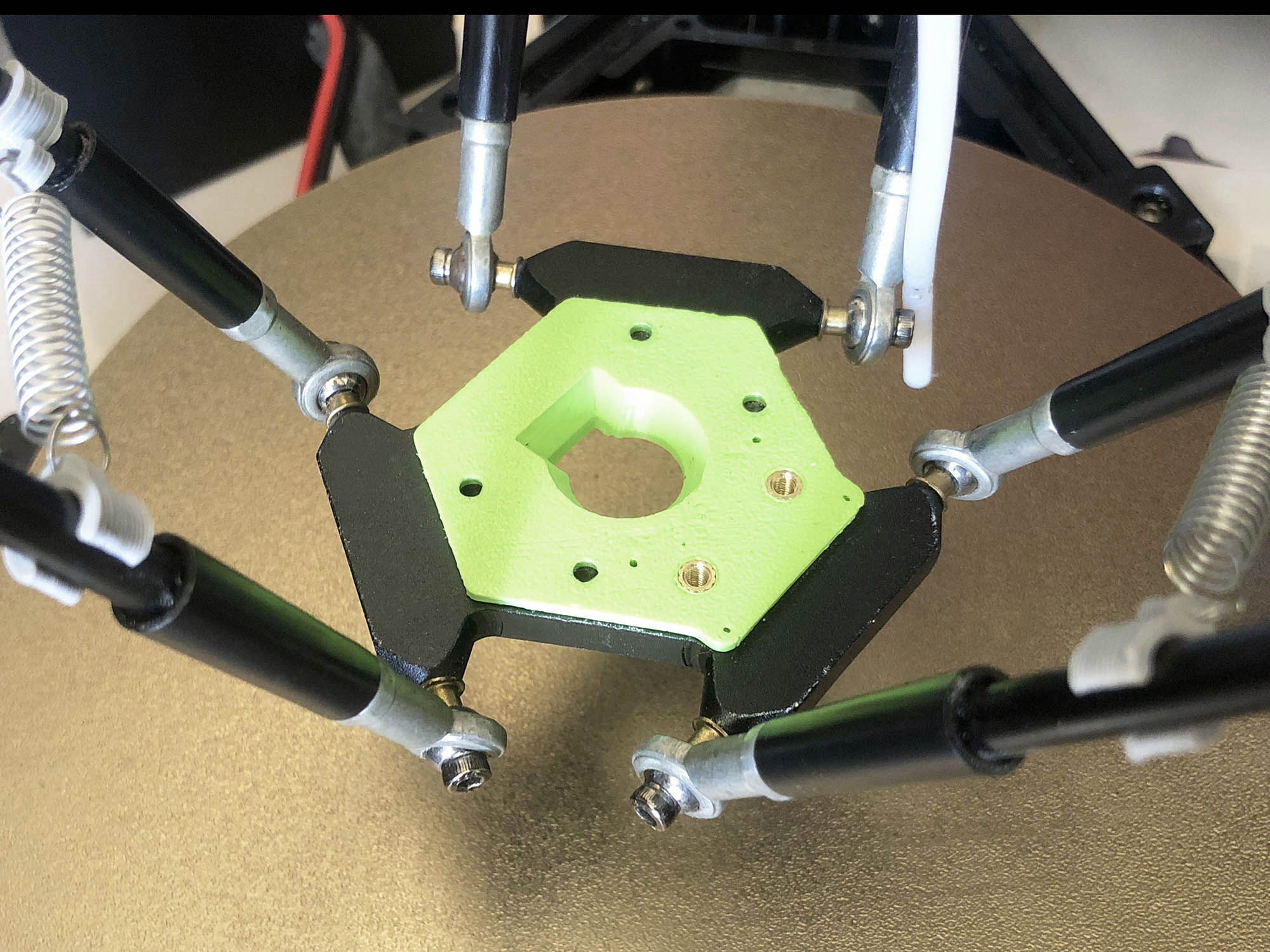

To assemble the different parts you'll need M3x4.6x5.7mm threaded inserts and M3 screws. I use hex socket head screws but you can use whatever type you prefer.

If you decide to use the improved hotend cooling system, you'll also need 4 M3 nuts to attach the fan duct (heatsink_4010_fan_duct).

Add threaded inserts, in the holes meant for that purpose, on the following parts:

- body: 16 inserts>

- effector_top_plate: 2 inserts

- z_probe_support: 2 inserts

Note all holes aren't used for the assembly of the toolhead. Some of them are left free so you can attach your own parts. You can, for examples, design parts for cables routing, to support different models of probes, etc.

For the assembly I use the shortest possible screws to keep the weight of the head as light as possible.

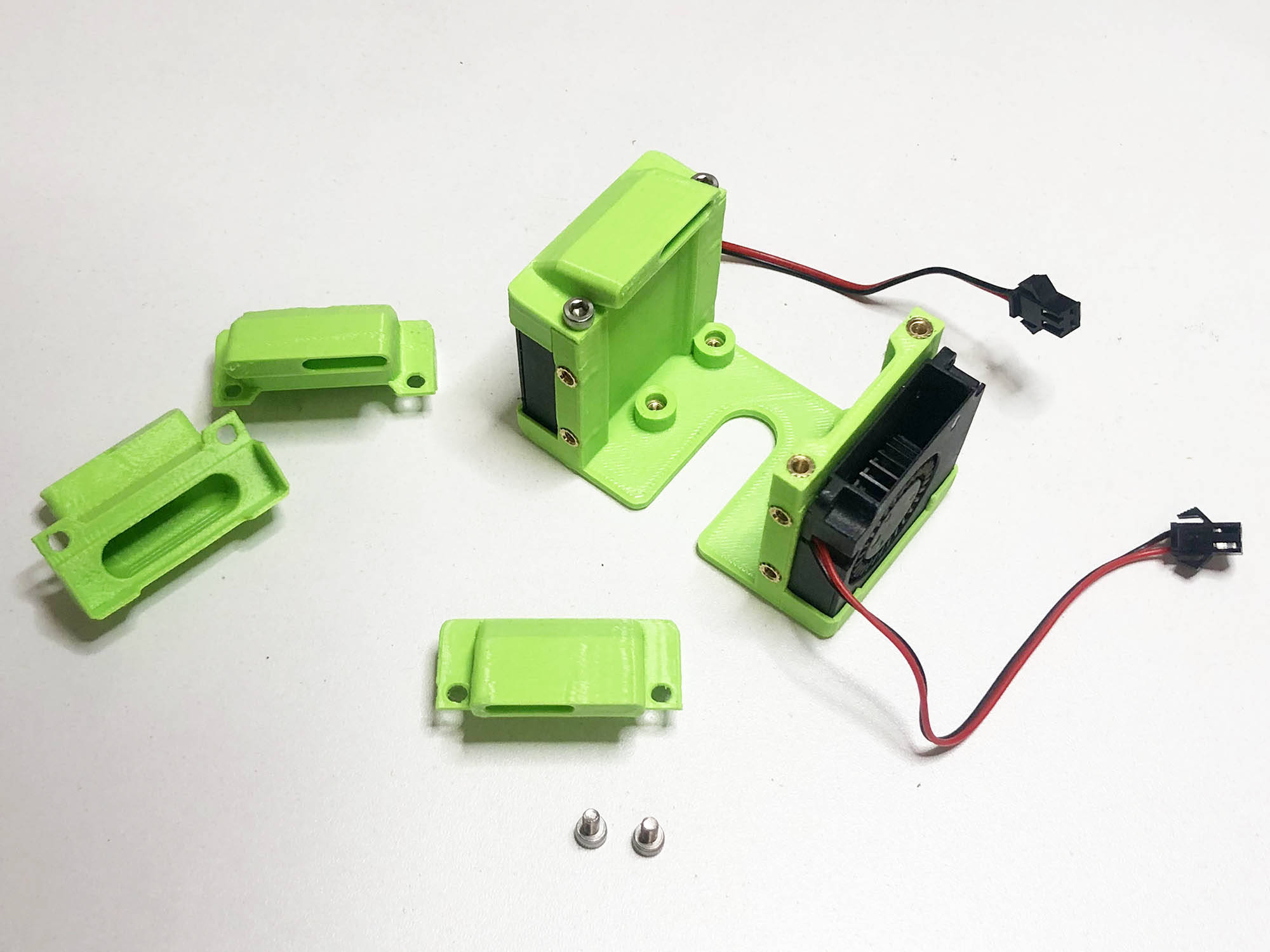

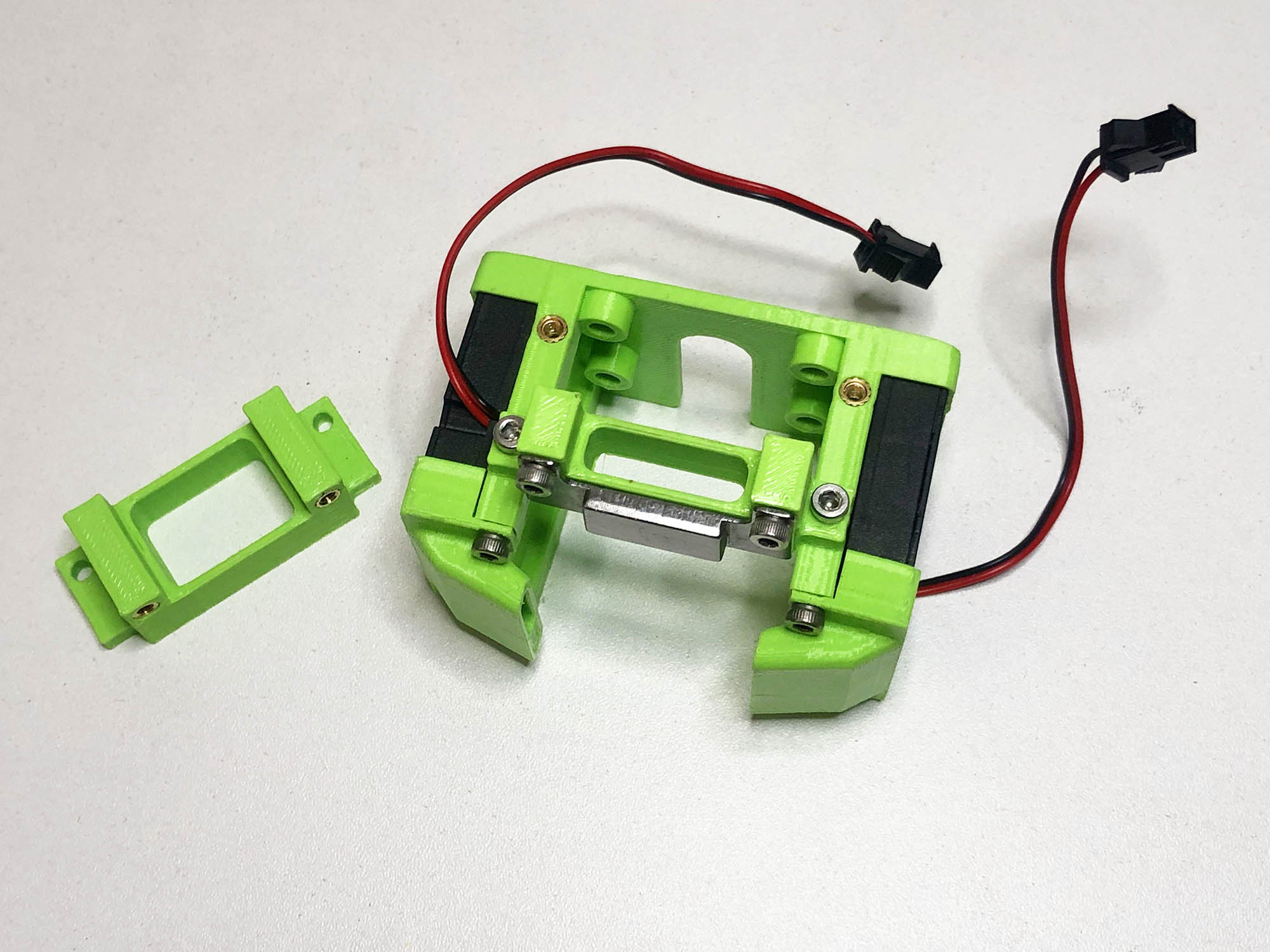

Part cooling fans and ducts

You need to print 2 air ducts (left and right). Two versions are available, one for V6 and one for VOLCANO sized hotends. The tallest ones are for VOLCANO.

Anycubic Z probe V2 mount holder

Optional hotend (coldend) silent cooling system with 4010 Sunon fan

!

!

!

!

Attaching the toolhead using the parts labeled body_fixation_V6 and effector_top_plate

Printer and firmware setup

After you replaced the hotend you must do a PID calibration (PID autotune).

The height has been modified with the installation of this toolhead so you also need to do a Delta calibration and set the new Z axis' height.